Challenge

The purpose of this new Electrochlorination plant was to manufacture, store and dose Hypochlorite which has now replaced the existing chlorine drum store and dosing system. This project was necessary to reduce the risk associated with the storage of large quantities of chlorine gas on on this Tier 1 COMAH site. After careful consideration by all parties, Picow accepted and then were entrusted by our client to complete this project under very demanding timescales. In order to achieve these timescales, it was necessary from the outset for Picow and our clients engineers to work very closely throughout the process to allow the design documents to be issued to site on a “just in time” basis to facilitate the flow of the installation seqeuncing of the project.

Solution

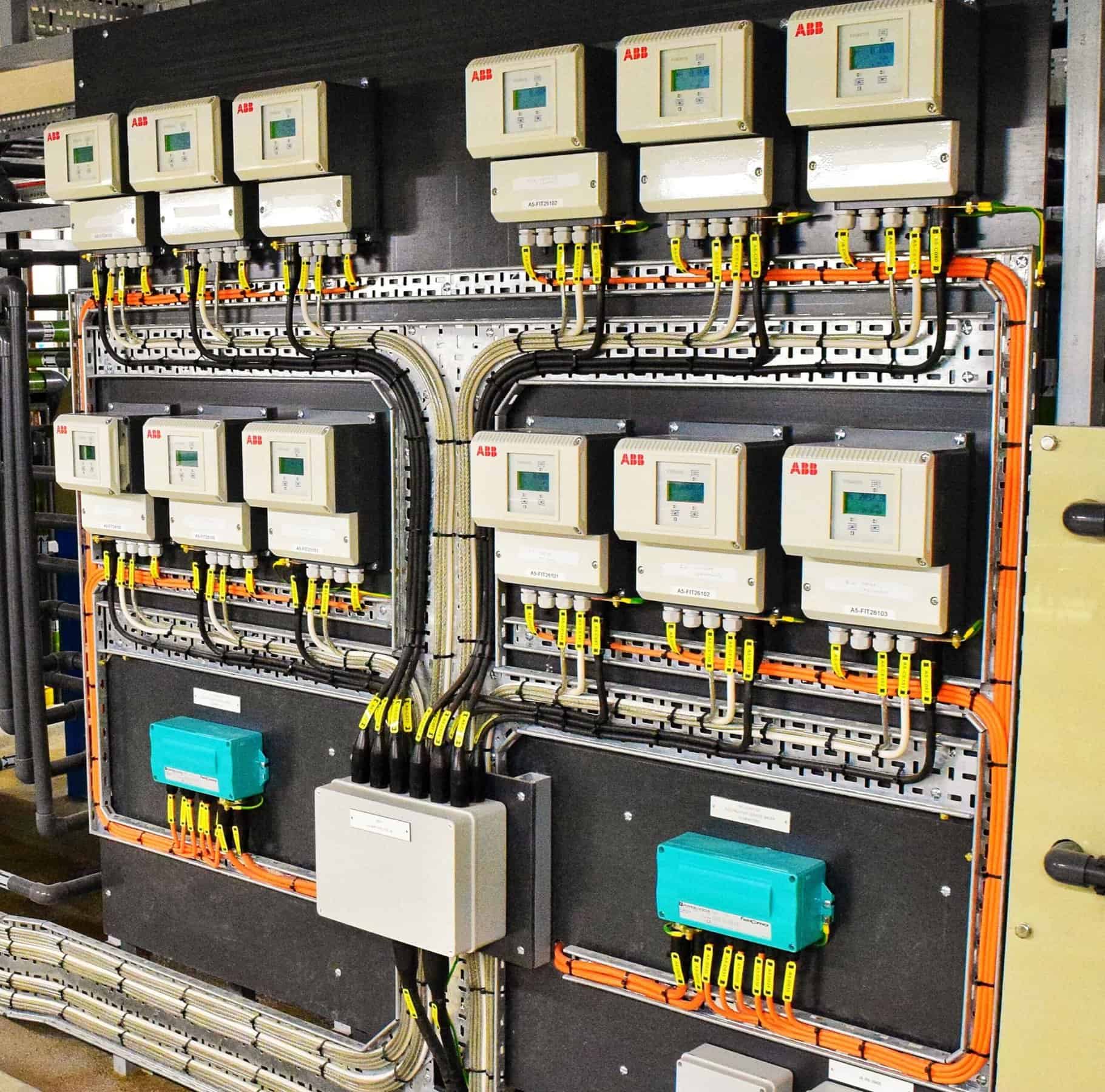

With a complex electrical design in toe, generally our scope involved the full electrical installation including primary low voltage distribution, primary and secondary cable management systems, hardwired power and control cabling to instruments and control panels, Profibus DP & PA networks, fibre optic networks, general building services power and lighting, trace heating power and control systems and also fire and intruder alarm systems. The above installations incorporated hazardous area design, installation and inspections in accordance with our clients DSEAR Risk Assessment

Outcome

Despite the constraints that a “just in time” design can bring, our clients initial decision to award Picow this contract was borne from our experience and expertise in this sector and general knowledge of WIMES standards. This ensured that our labour force needed little time to digest new design information and also the chance for error was greatly reduced. The quality of workmanship on this project was second to none and is testament to the skill of our workforce and the collaborative nature in which the project was delivered.